It is widely promoted throughout the biomass industry that a safety mechanism within a wood pellet store is needed to decelerate pellets during filling, minimising and preventing damage to the fuel and store walls.

Impact protection mats are often fitted to serve this function; however, new technologies, such as the cyclone system present in Grant’s pellet stores, offer alternative, more advanced solutions.

During deliveries, every effort should be made to reduce the impact inflicted on the pellets. For example, the route from the delivery truck to the bulk pellet store should be as straight as possible, avoiding bends in the pipework which could damage the pellets in transit. Meanwhile, inside the pellet store, any screws within must be fixed so as to not damage the pellets as they fill the store.

Additionally, many stores are fitted with a protection mat which is positioned so as to absorb the impact of the pellets. These must be made of anti-abrasive and tear resistant materials because the pellets hit their surface at very high speeds and they must also be positioned so as to flex and move during deliveries. In order to be functional, impact mats must be of sufficient size so that the full stream of pellets is caught. Furthermore, the location of the mat is crucial; if it is fitted too close to the store wall, it cannot flex and therefore not absorb the force. Thus, the effectiveness of an impact mat is often determined by how it is fitted potentially leaving room for error.

The mats also affect how the stores fill, splitting the pellets and dust. When the pellets hit, they rebound and fall to one side of the store with the dust accumulating on the opposite side. This means that as the pellets are drawn out of the bottom of the store by the auger, the dust will be drawn into the auger separately. When it is filled with dust on its own, the auger cannot move the material because it is too light – augering dust is similar to turning water so a stalemate is created: the dust clogs the auger, preventing the pellets which are on the top from feeding into the auger and consequently into the boiler.

Grant developed a range of wood pellet stores which vary in size from 500kg up to 6 tonne units. The stores allow for the bulk storage of wood pellets, enabling the homeowner to purchase their biomass boiler’s fuel in large quantities which often proves to be more cost effective than buying smaller bags of pellets.

Grant’s stores are not fitted with an impact mat. Instead, 1.5tonne and larger units utilise a unique cyclone system which can offer more effective protection compared to traditional methods, ensuring the safe delivery of pellets.

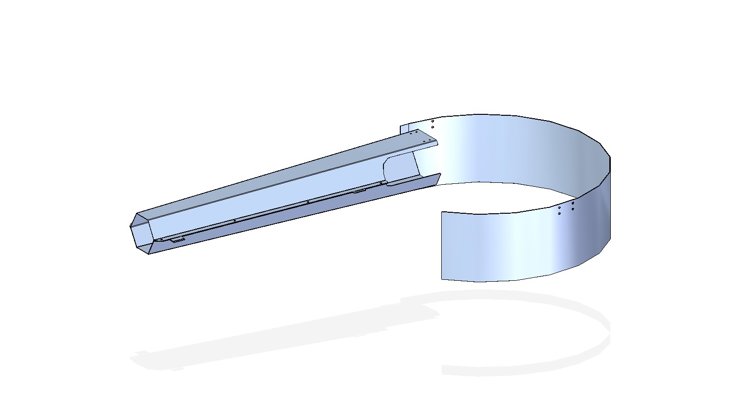

Fitted at the top of the pellet store is a curved structure which is designed to reduce the impact of the pellets upon delivery while also ensuring that the store is evenly filled. The pellets enter via the tube section of the cyclone structure and follow the curve. As the pellets move around the curve, they lose their speed and, with gravity, gently fall to the bottom. This cyclone system slows the speed with which the pellets fill the store; rather than hitting an impact mat at high speed, the pellets’ velocity is reduced as they move around the curve so that when they fall, their speed is significantly reduced.

When the pellets drop from the cyclone system, they do so without splitting into two piles of dust and pellets. The wood pellets fill the store evenly, collecting from the centre upwards rather than from the sides. Not only does the cyclone system ensure that the pellets and any dust uniformly fill the store, it also reduces the total amount of dust that is generated during the delivery process.

Grant’s wood pellet stores are also fitted with a pressure relief vent at the top. This is a rectangular opening that adjusts and rises according to the air pressure within the unit. During the delivery process, the pressure towards the top of the store quickly increases. The vent controls this increased pressure preventing damage to the store. Furthermore, the cyclone system ensures that the formation of the pellets allows for greater air space at the top of the store. Conversely, pellets within a store fitted with an impact mat form into a shape that leaves little air space at the top of the store creating very high pressure which could potentially damage the store. Grant’s cyclone system and pressure relief vent work together to reduce and manage high pressure levels within the store.

It is very important that when filling Grant pellet stores, deliveries should only be fed into the store via the fill tube. Wood pellets must not be blown into Grant stores through the vent tube because this will force the pellets to bypass the cyclone mechanism.

Filling via the vent tube is usually only carried out to ensure pellets are evenly distributed; however, the cyclone system in Grant stores removes the need for this step allowing pellets to accumulate from the centre and along the sides.

Grant prides itself on its research and development of quality heating appliances and accessories. The cyclone system within Grant’s wood pellet stores has modernised traditional techniques. It uses the principal behind older methods – the need to prevent pellets from hitting the store sides at high speed – and approaches it from a new, innovative angle. Rather than making the pellets hit one surface to avoid another, the cyclone technology significantly reduces the pellets’ speed during delivery without them impacting an intermediary surface at high speed. Grant stores are designed to protect the wood pellets from the moment they enter through to the time they reach the auger. Homeowners can benefit from the advantages of bulk pellet storage while having the peace of mind that their boiler’s fuel is safely and securely stored.

For more information about Grant’s wood pellet stores, please click here.